MATELION focuses on the LFP prismatic cell,widely used in electric tractors, mining machinery, energy storage, forklifts and ships. Our LFP prismatic cells have been tested by the market for more than 5 years,have been and the cell technology has been continuously optimize.

Production Desciption

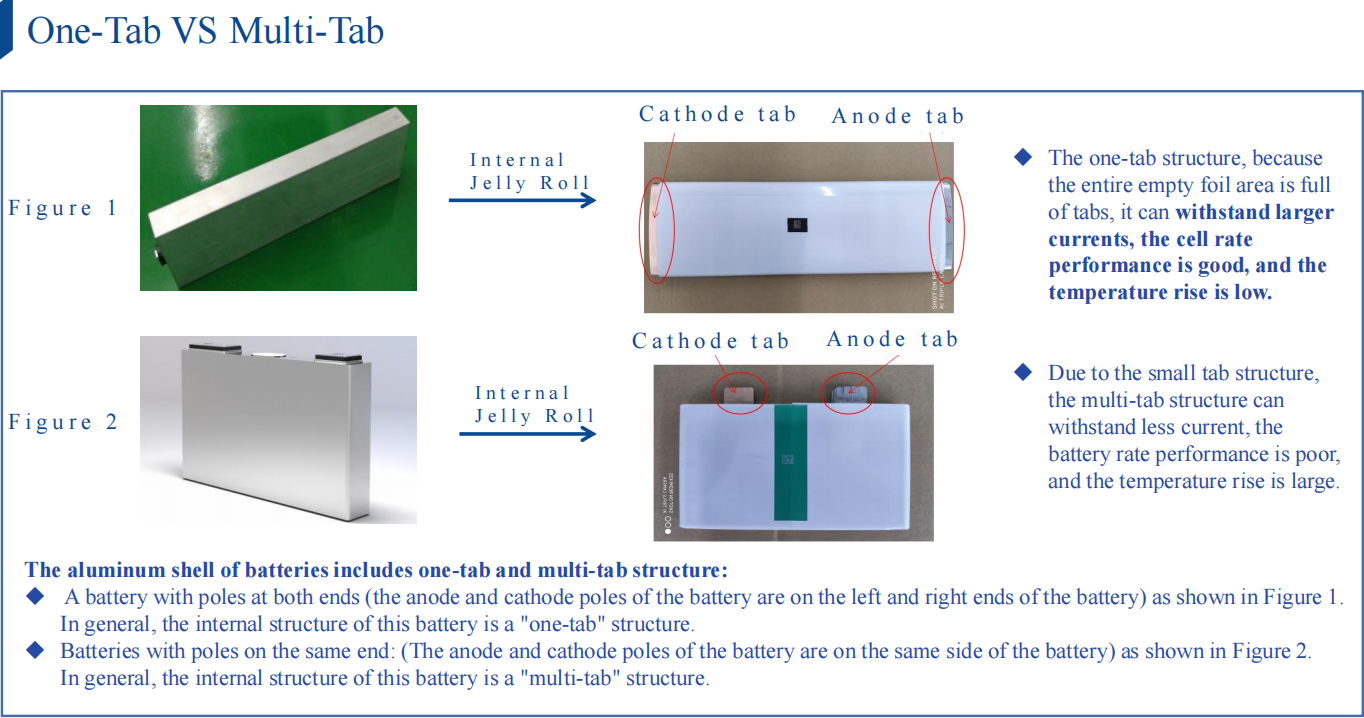

The super cell is the 280Ah LFP prismatic cell which is designed with unique structure of one-tab, that the taps stand out of the two ends of the cell. Because the entire empty foil area is full of tabs, it can withstand larger current and the cell C-rate performance is very good. Besides,the temperature rise is obviously lower than common LFP primatic cells .

LFP Prismatic Cells are lithium iron phosphate battery cells designed with rigid aluminum or steel casing, offering exceptional safety, structural stability, and long-term reliability. LFP (LiFePO4) chemistry is widely recognized as one of the safest lithium battery technologies, making prismatic LFP cells the preferred choice for large-scale energy storage systems, electric vehicles, and industrial power applications.

As a professional LFP Prismatic Cells manufacturer and supplier, we provide high-quality lithium battery cells that deliver stable performance, long service life, and excellent consistency for battery pack integration.

With the advantage of simple arrangement,convenient maintenance and the higher space utilization rate, it can be very flexibly suitable for various types of customers and application scenarios.

Compared to cylindrical batteries and pouch batteries, our square batteries possess five core competitive advantages, creating practical value for your end products:

1. Robust structure, outstanding safety performance

The battery is encapsulated with a high-strength aluminum alloy shell, which has strong resistance to impact and vibration, effectively preventing external mechanical damage; it is also equipped with an explosion-proof valve design, which can automatically release pressure when the internal pressure of the battery is abnormal, preventing thermal runaway risks at the source. The product has passed multiple rigorous tests such as overcharge, compression, puncture, and fire, meeting automotive-grade (IATF16949), industrial-grade high safety standards, and is suitable for stable operation under complex conditions.

2. Standardized design, higher integration efficiency

The size of the battery cell and the height of the interface are standardized, allowing for direct combination of series and parallel to form a battery pack without the need for additional complex fixing brackets and buffering structures, significantly reducing the difficulty and cost of battery pack integration; at the same time, the consistency of standardized battery cells is easier to control, which can effectively improve the overall cycle life and charging and discharging efficiency of the battery pack, especially suitable for large-scale energy storage and new energy vehicle batch application scenarios.

3. Balanced energy density and rate performance

Our square batteries can achieve an energy density of 250-300Wh/kg, supporting high-rate discharging ranging from 5C to 10C, which can meet the high current requirements of acceleration and climbing in new energy vehicles, as well as the fast charging and discharging scenarios of energy storage systems; the internal resistance of the battery cell is as low as ≤30mΩ, with low heat generation during charging and discharging, and a cycle life of over 1500 times (remaining capacity ≥80%), balancing both range and durability.

4. Strong temperature adaptability, covering all scenarios

The working temperature range of the battery cell is wide, from -30℃ to 60℃. In low-temperature environments, the capacity retention rate is ≥70%, and in high-temperature environments, the cycle stability does not decline. It can meet the power supply requirements of energy storage stations in cold regions, high-temperature industrial equipment, and outdoor construction machinery and other special scenarios.

5. Large-scale production, significant cost advantage

We have a fully automated square battery production line, using a roll-to-roll / laminated double-mode production process, which can meet the production of all specifications from Ah-level small cells to hundreds of Ah-level large cells; large-scale production effectively reduces costs, compared to soft-pack batteries of the same performance, it can save 8%-15% of cell procurement costs for customers.

| Model No. | Chemistry | Nominal Capacity (Ah) | Rated Voltage (V) | Max. Continuous Discharge Current | Max. Charge Current | Weight (kg) | Size (mm) | Cycle Life | DataSheet |

| MATE39514896-50Ah | LiFePO4 | 50 | 3.2 | 1C | 1C | 1.18 | 39.5x148x96 | 4000 Cycles @1C, 25℃ | |

| MATE27173204-100Ah | LiFePO4 | 100 | 3.2 | 1C | 1C | 2.13 | 27x173x204 | 4000 Cycles @1C, 25℃ | |

| MATE37130200-105Ah | LiFePO4 | 105 | 3.2 | 3C | 1C | 1.98 | 37x130x200 | 3500 Cycles @1C, 25℃ | |

| MATE7914897-120Ah | LiFePO4 | 120 | 3.2 | 1C | 1C | 2.41 | 79x148x97 | 3000 Cycles @1C, 25℃ | |

| MATE35173207-150Ah | LiFePO4 | 150 | 3.2 | 1C | 1C | 2.82 | 35x173x207 | 3000 Cycles @1C, 25℃ | |

| MATE54173200-205Ah | LiFePO4 | 205 | 3.2 | 1C | 1C | 3.98 | 54x173x200 | 6000 Cycles @1C, 25℃ | |

| MATE54173200-230Ah | LiFePO4 | 230 | 3.2 | 1C | 1C | 4.13 | 54x173x200 | 4000 Cycles @1C, 25℃ | |

| MATE71173204-280Ah | LiFePO4 | 280 | 3.2 | 1C | 1C | 5.37 | 71x173x204 | 6000 Cycles @1C, 25℃ | |

| MATE71173204-302Ah | LiFePO4 | 302 | 3.2 | 1C | 1C | 5.4 | 71x173x204 | 4000 Cycles @1C, 25℃ |

To meet the differentiated needs of customers from various industries, we have developed exclusive solutions covering the entire chain from solution design to after-sales maintenance:

1. Battery Solution for New Energy Vehicles

Challenges Addressed: For passenger cars, commercial vehicles, and logistics vehicles, we offer a square cell + battery pack + BMS integrated solution; support for optimizing cell grouping efficiency to enhance battery pack energy density; customize thermal management systems to solve issues of uneven heat dissipation and reduced battery pack range at low temperatures.

Value-added Services: Assist customers in completing the matching and debugging of battery packs and the vehicle, provide CCC, UN38.3, etc. certification support, and shorten the product launch cycle.

2. Exclusive Solution for Energy Storage Systems

Challenges Addressed: For household energy storage, industrial and commercial energy storage, and grid energy storage scenarios, we provide high consistency square cell modules; equipped with intelligent BMS and EMS energy management systems to achieve intelligent charging and discharging control and grid peak-valley arbitrage; support modular assembly, flexibly adapting to different energy storage capacity requirements.

Value-added Services: Provide overall design and installation guidance for the energy storage system, and offer 7×24-hour remote monitoring and fault services after sales.

1. R&D Strength: The company has a R&D team, equipped with a national-level battery testing laboratory, focusing on innovative square battery materials, structural optimization, and BMS algorithm development, with cumulative related patents and technical indicators at the industry-leading level.

2. Production Strength: The fully automated production line adopts MES production management system, achieving full traceability of the production process; equipped with online detection equipment to conduct 100% screening of key parameters such as cell voltage, internal resistance, and capacity, ensuring that the consistency deviation of the factory-produced cells is ≤ 2%.

3. Quality Control and Certification: Obtained ISO9001 quality management system, ISO14001 environmental management system, IATF16949 automotive industry quality system certifications; products comply with CE, UL, UN38.3 and other international certification standards, meeting the requirements for market access in both domestic and foreign markets.

4. Service Strength: Provide one-on-one customer managers + technical engineers for connection services; after sales, provide lifetime technical consultation, and respond quickly to product quality issues to ensure that the production progress of the customer is not affected.

Compared with NCM or NCA lithium batteries, LFP prismatic cells offer:

Higher safety and lower fire risk

Longer cycle life and lower degradation rate

Better performance under high temperature

Lower environmental impact without cobalt

More stable output for long-term energy storage

Although their energy density is slightly lower, their safety and durability make them far more suitable for industrial and large-scale applications.

As a reliable Industrial Rechargeable Batteries Cells manufacturer and supplier, we focus on:

Strict quality control and testing processes

High cell consistency for mass production

Stable long-term supply capability

Flexible customization support

Competitive pricing and fast delivery

Our LFP prismatic cells are designed to meet demanding industrial requirements, ensuring safety, reliability, and long-term performance.

Our square batteries not only possess the stability and reliability of hard-shell batteries, but also enjoy the cost advantages of large-scale production. Moreover, they can provide you with customized application solutions. Choosing us means you will not only receive high-quality battery cells, but also a long-term cooperative partner. We look forward to jointly exploring the potential applications of square batteries in more fields and achieving mutual benefit and win-win results!